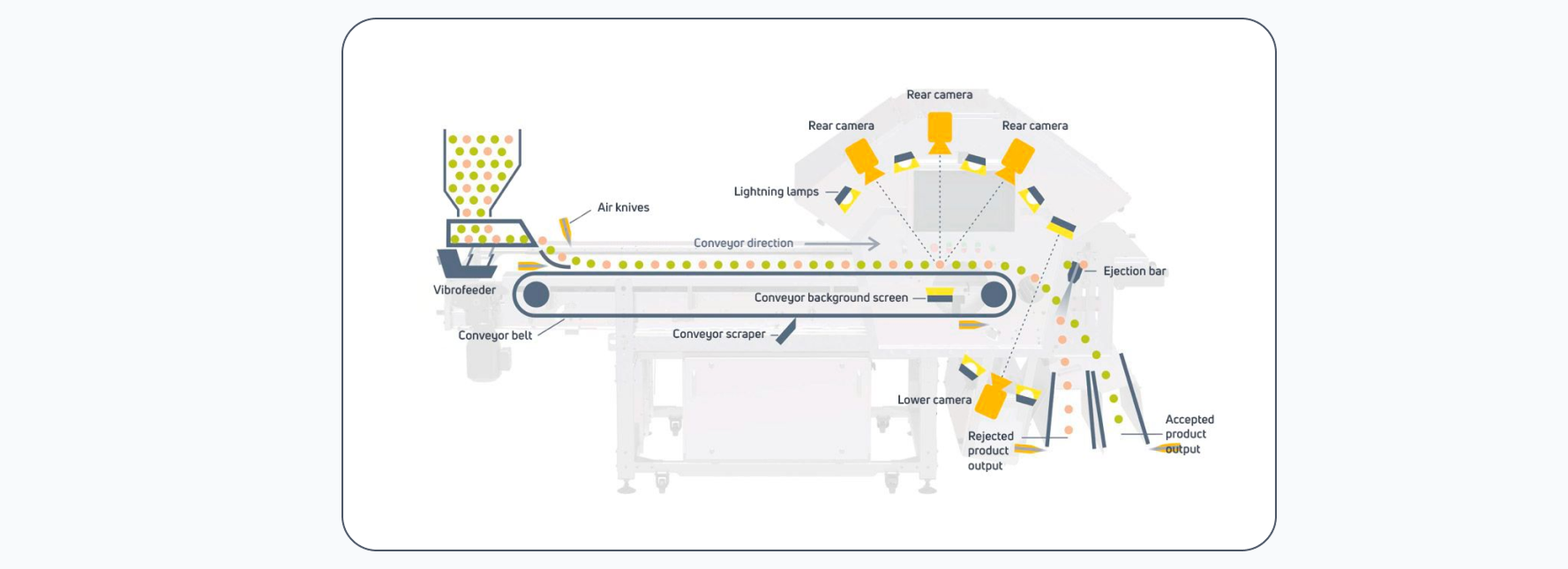

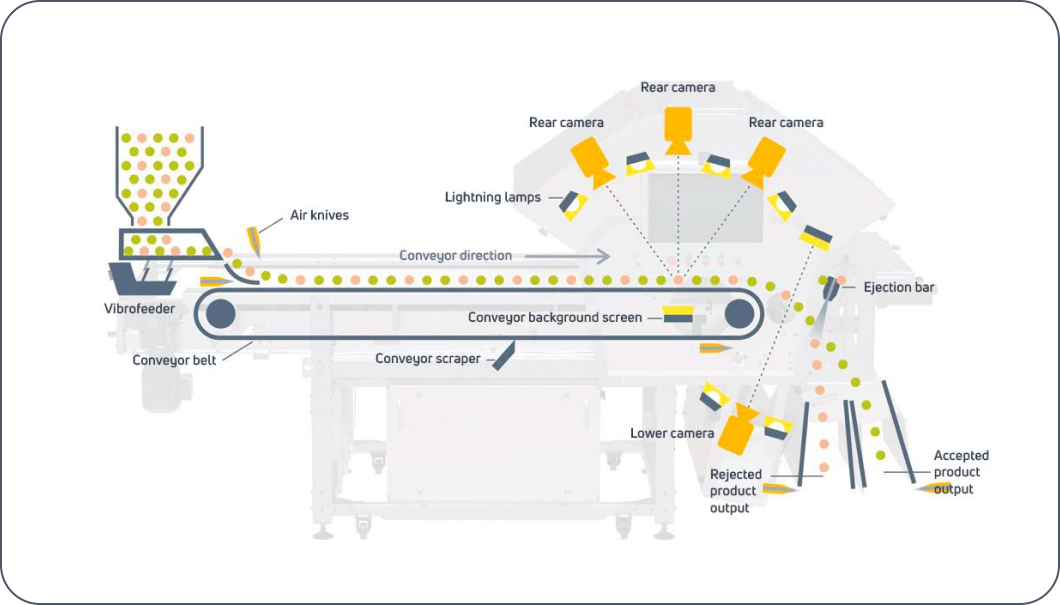

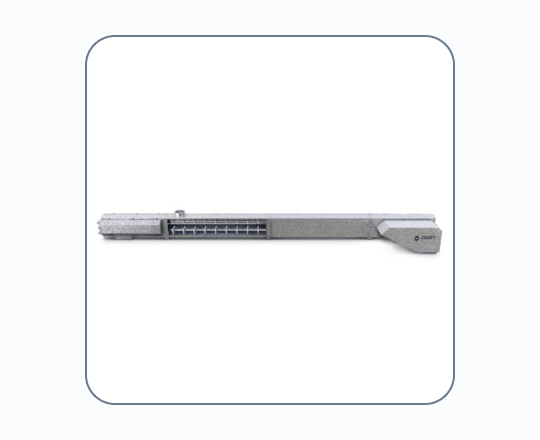

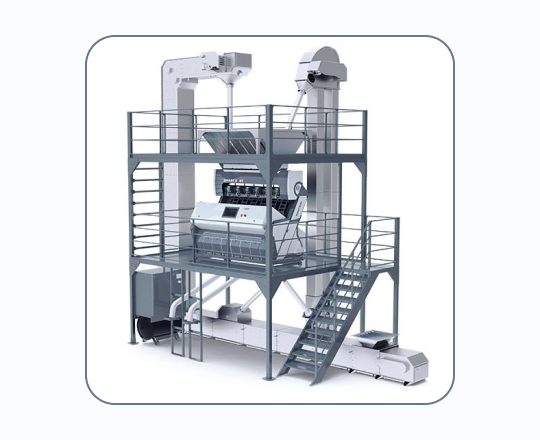

Horizontal optical sorter

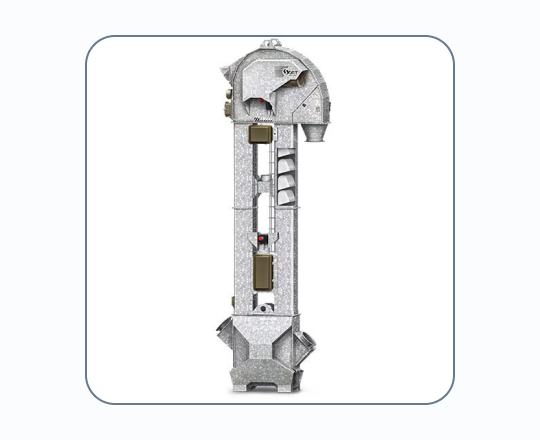

Horizont

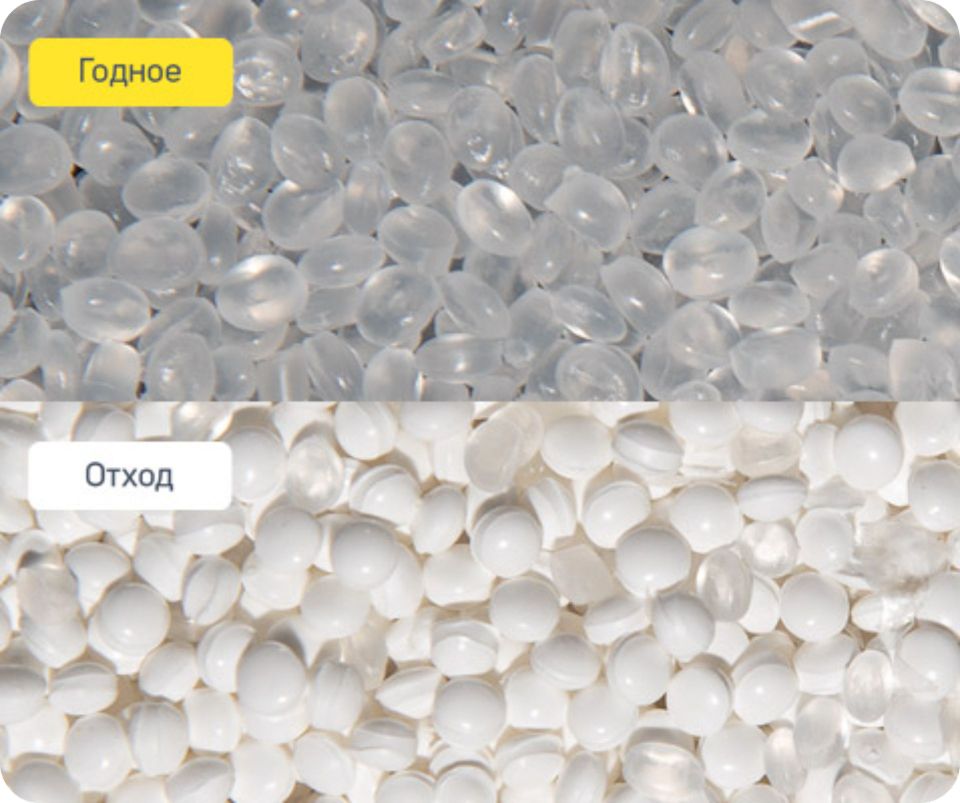

Optical sorters “Horizont” are designed for color sorting of food and non-food bulk materials by extracting visually different impurities, for example, from nuts, chips and flakes, vegetables, seafood, berries and other fresh, dried or frozen fruits, metals, minerals and plastics.